Visit our new and improved web site at www.mrf-furnaces.com.

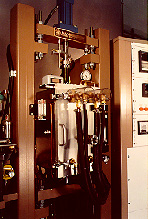

HIGH TEMPERATURE VACUUM OR CONTROLLED ATMOSPHERE FRONT OPENING, MULTI-APPLICATION, LABORATORY FURNACE

HOT ZONE SIZES 3" DIA X 8" HIGH, SINGLE PHASE 4" DIA X 6" HIGH, SINGLE PHASE 4" DIA X 8" HIGH, SINGLE PHASE HOT ZONE MATERIALS TUNGSTEN, MOLYBDENUM, OR GRAPHITE HOT ZONES AVAILABLE |

|

|||||

TEMPERATURES UP TO 2000 DEGREES C

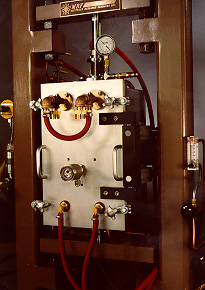

OPERATING PRESSURES FROM 2 PSIG TO 10-6 TORR

|

The basic furnace is available with either a graphite heating element with

rigid fibrous graphite shields or a tungsten mesh heating element with

tungsten refractory metal shielding. All hot zone components are easily accessed for service. Sight ports and thermocouple ports are provided. Additional ports can be supplied at your request. The full opening front door provides fast and easy access to your work. The furnace design lends itself to hot pressing, physical testing, or firing your sample on a hearth plate or in a crucible. |

|

|

The MRF CommitmentPersonal ServiceAccurate QuotesIntelligent Designs Innovative EngineeringQuality Workmanship On-Time DeliveryDependable Performance Technical SupportField Service |

Suncook Business Park

Rt. 28 & Lavoie Drive

Suncook, New Hampshire 03275

Voice: (603)485-2394

Fax: (603)485-2395

Email: [email protected]