Visit our new and improved web site at www.mrf-furnaces.com.

HIGH TEMPERATURE VACUUM AND CONTROLLED ATMOSPHERE PHYSICAL TESTING FURNACE

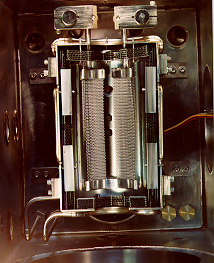

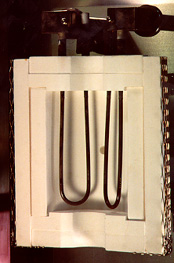

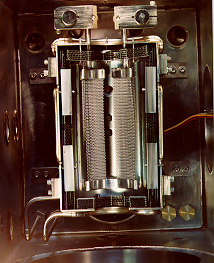

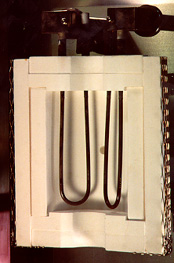

The standard testing unit comes with top and bottom stainless steel

testing rods and metal sealed bellows.

Hot rods are designed on request.

|

|

APPLICATIONS

- ANNEALING

- BRAZING

- CERAMIC FIRING

- DEGASSING

- HOT PRESSING

- HEAT TREATING

- MELTING

- SINTERING

- TENSILE TESTING

This testing unit is designed to house many different extensometers.

The access port in the side of the chamber makes for easy alignment of

the specimen with the extensometer.

|

TEMPERATURES UP TO 2500 DEGREES C

OPERATING PRESSURES FROM 2 PSIG TO 10-6 TORR

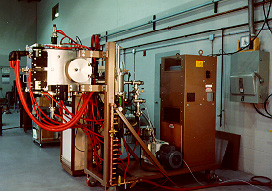

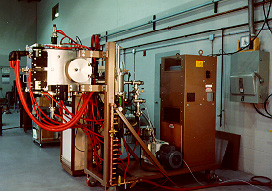

The MRF Pshysical Test Furnace comes to your lab preprogrammed and ready

to operate as soon as your basic utilities have been connected. All

water, gas plumbing and wiring are done at the factory and your system

arrives completely tested.

|

|

The basic furnace has a tungsten refractory metal hot zone, with a

tungsten mesh heating element.

All hot zone components are easily accessed for service. Sight ports

and T.C.'s are provided. Additional ports can be supplied at your

request.

Designed to adapt to most material testing machines.

|

|

|

This MRF testing unit has been designed to incorporate many different

types and sizes of hot zones. The furnace can be supplied with a

ceramic hot zone for operation to 1750 Degrees C in oxidizing

atmospheres. This furnace is also designed to install a graphite hot

zone for operation to 2500 Degrees C in a vacuum or inert gas

environment.

Several vacuum systems are available including, but not limited to, a

diffusion system, turbo pumping system or an evacuation system. The

system can be pumped down to the desired vacuum level and back filled

with the desired inert gas.

Gas systems are available for a variety of process gases. Reducing gas

can also be used when the factory is notified before manufacturing

starts. Please consult with MRF engineers for special applications or

requests.

The power supply is designed to accommodate a ramp rate of 100 Degrees

C/min. up to operating temperature. Three phase SCR control provides an

economical and efficient means of modulating power to the heating

element in a reliable and accurate fashion. Water cooled power cables

supply power to the heating element from the main step down transformer.

Volt and amp meters are supplied to visually monitor the power the

furnace is using.

For truly extraordinary applications, MRF specialists can design and

build one-of-a-kind furnaces that meet unique and demanding needs of the

R&D industry. You'll appreciate the "can do" attitude at MRF.

The MRF Commitment

Personal ServiceAccurate QuotesIntelligent Designs

Innovative EngineeringQuality Workmanship

On-Time DeliveryDependable Performance

Technical SupportField Service

Return to our Home page

Visit our new and improved web site at www.mrf-furnaces.com.

Suncook Business Park

Rt. 28 & Lavoie Drive

Suncook, New Hampshire 03275

Voice: (603)485-2394

Fax: (603)485-2395

Email: [email protected]